Home > Our Services > Destructive & Non destructive Test

Our Services

Destructive & Non-destructive test

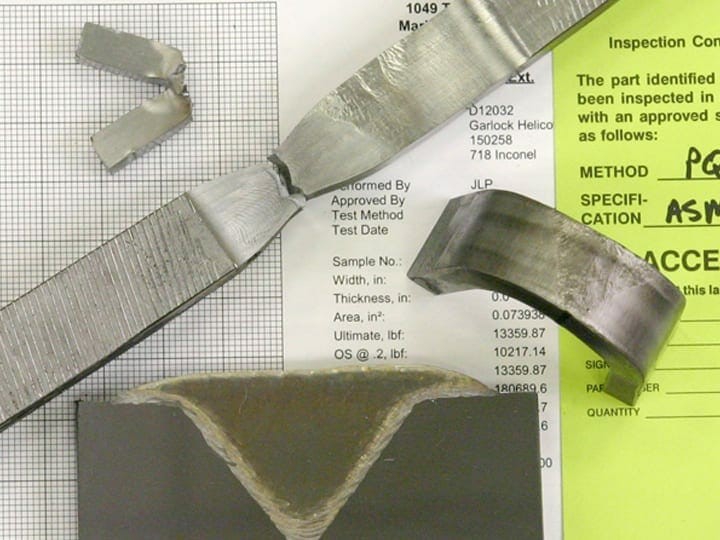

Destructive test

Destructive testing aims to deform or destroy a material to analyze its point of failure.

On the other hand, non-destructive testing uses inspection methods that do not damage a material or asset in any way.

Inspectors use DT and NDT in different scenarios.

Destructive testing aims to deform or destroy a material to analyze its point of failure.

On the other hand, non-destructive testing uses inspection methods that do not damage a material or asset in any way.

Inspectors use DT and NDT in different scenarios.

Non Destructive test

Non-destructive testing (NDT) is a testing and analysis technique used by industry to evaluate the properties of a material,

component, structure or system for characteristic differences or welding defects and discontinuities without causing

damage to the original part.

Non-destructive testing (NDT) is a testing and analysis technique used by industry to evaluate the properties of a material,

component, structure or system for characteristic differences or welding defects and discontinuities without causing

damage to the original part.

Macro etching test

Metal macroetch inspection is a non-destructive testing technique used to examine the macrostructure of metallic materials. It involves etching the surface of a metal sample to reveal its macroscopic features, such as grain size, inclusions, segregation, and discontinuities.